9 Key Business Process Improvement Methods for 2025

In a competitive market, operational efficiency is not just an advantage; it's a necessity. The ability to consistently refine how work is done separates industry leaders from the rest of the pack. This is the core purpose of business process improvement (BPI), which provides structured frameworks for identifying inefficiencies, eliminating waste, and enhancing value delivery. For professionals in fields like legal, healthcare, and compliance, where precision and reliability are paramount, adopting a systematic approach to optimization is crucial. These methodologies are not about minor adjustments; they are about fundamentally re-engineering workflows to boost productivity, reduce errors, and elevate service quality.

This guide moves beyond theory to provide a practical roadmap. We will dissect nine of the most powerful business process improvement methods, offering a clear-eyed view of what makes each one effective. You will gain actionable insights into frameworks like Lean, Six Sigma, Kaizen, and Agile, among others. For each methodology, we will explore:

- Core principles and objectives.

- Step-by-step implementation guidance.

- Real-world examples tailored to professional services.

- Best practices for achieving measurable results.

Whether your goal is to make small, continuous enhancements or to execute a complete operational overhaul, this article will equip you with the knowledge to select and apply the right framework. By mastering these BPI strategies, you can transform your organization’s processes from a source of friction into a powerful driver of sustainable growth and competitive distinction. The following sections will provide the detailed, practical survey needed to begin that transformation.

1. Lean

Lean is a systematic methodology that fundamentally shifts an organization's focus toward maximizing customer value while relentlessly minimizing waste. Originating from the Toyota Production System, this approach is one of the most powerful business process improvement methods because it provides a clear framework for identifying and eliminating non-value-added activities from any workflow. It redefines efficiency not as doing more work, but as delivering more value with less effort, time, and resources.

The core principle of Lean is the identification and elimination of the "eight wastes" (often remembered by the acronym DOWNTIME): Defects, Overproduction, Waiting, Non-utilized talent, Transportation, Inventory, Motion, and Extra-processing. By systematically targeting these areas, organizations can dramatically streamline operations.

When to Use Lean

Lean is particularly effective when the primary goal is to increase speed and efficiency, reduce operational costs, and improve customer satisfaction. It is ideal for processes riddled with delays, bottlenecks, or excessive steps. For instance, a healthcare provider can use Lean to reduce patient wait times, while a legal firm can apply it to accelerate document review cycles, ensuring faster client service without compromising quality.

How to Implement Lean

Implementing Lean requires a cultural shift towards continuous improvement. Here are actionable steps to get started:

- Map the Value Stream: Begin by creating a value stream map. This visual tool helps you document every step in a specific process, from start to finish, clearly distinguishing between value-added and non-value-added activities.

- Empower Your Team: Train employees at all levels in Lean principles. The individuals closest to the work often have the best insights into sources of waste and potential solutions. Empower them to identify and implement changes.

- Focus and Iterate: Don't try to fix everything at once. Select one specific area or process identified in your value stream map and apply Lean principles. For a more comprehensive look at process optimization, you can learn more about business process streamlining.

- Measure and Adapt: Continuously track key performance indicators (KPIs) like cycle time, error rates, and resource utilization. Use this data to validate improvements and identify new opportunities for refinement.

2. Six Sigma

Six Sigma is a highly disciplined, data-driven methodology focused on eliminating defects and reducing process variation to achieve near-perfect quality. Developed at Motorola and famously championed by General Electric, it stands out as one of the most rigorous business process improvement methods available. Its goal is to bring processes to a level where there are fewer than 3.4 defects per million opportunities (DPMO), creating a framework for consistent and predictable business outcomes.

The core of Six Sigma lies in its statistical approach to problem-solving. It uses two key methodologies: DMAIC (Define, Measure, Analyze, Improve, Control) for existing processes and DMADV (Define, Measure, Analyze, Design, Verify) for new processes or products. By leveraging statistical analysis, organizations can pinpoint the root causes of errors and make precise, data-backed improvements rather than relying on guesswork.

When to Use Six Sigma

Six Sigma is most powerful when the primary objective is to solve complex problems, drastically reduce defect rates, and improve the quality and consistency of a process output. It is especially suited for environments where even small errors can have significant consequences. For example, a financial institution like Bank of America used Six Sigma to improve data accuracy in its reporting processes, while a manufacturing company like 3M applies it to optimize production lines and ensure product specifications are consistently met.

How to Implement Six Sigma

Successful Six Sigma implementation is a structured initiative that requires commitment and expertise. Here are the essential steps:

- Secure Leadership Buy-In: Six Sigma projects often require significant resources and cross-departmental collaboration. Strong, visible support from leadership is crucial for overcoming resistance and ensuring project success.

- Invest in Training and Certification: Build internal capability by training employees in Six Sigma methodologies. Certify key personnel as Green Belts, Black Belts, and Master Black Belts to lead and execute improvement projects effectively.

- Select the Right Projects: Not every problem requires a Six Sigma approach. Use a structured selection process to identify projects that are complex, tied to key business goals, and have a clear potential for significant financial or quality-related returns.

- Embrace a Data-First Culture: Equip your teams with the necessary statistical software and tools. Foster a culture where decisions are made based on data analysis and verifiable metrics, moving away from intuition-based adjustments.

3. Kaizen

Kaizen is a Japanese philosophy that translates to "change for the better" or "continuous improvement." It is a foundational approach among business process improvement methods that emphasizes making small, incremental, and ongoing changes. Rather than pursuing large-scale, disruptive overhauls, Kaizen focuses on empowering all employees, from the CEO to frontline workers, to identify and implement small enhancements in their daily work routines. This collective effort fosters a culture of sustained improvement and operational excellence.

The core principle of Kaizen is that many small improvements over time lead to significant long-term benefits in quality, productivity, and employee engagement. It is a mindset that sees every process as a work in progress, capable of being refined. This philosophy was central to the success of companies like Toyota, which used it to build a culture of relentless problem-solving and efficiency.

When to Use Kaizen

Kaizen is most effective when an organization wants to build a long-term culture of continuous improvement rather than just completing a one-off project. It is ideal for environments where you need to empower employees and foster a sense of ownership over processes. For example, a healthcare clinic can use Kaizen to encourage nurses and administrative staff to suggest and test small changes to patient intake forms or appointment scheduling, gradually reducing administrative errors and wait times. A law firm can apply it to refine its document management system, with paralegals suggesting minor tweaks that collectively save hours each week.

How to Implement Kaizen

Implementing Kaizen is about embedding a new way of thinking across the organization. Here are actionable steps to get started:

- Involve All Employees: Create a system where everyone is encouraged to submit ideas for improvement, no matter how small. Make it clear that every contribution is valued. This can be done through suggestion boxes, regular team huddles, or digital platforms.

- Start with Small, Low-Cost Changes: Focus on identifying minor issues or "pebbles in the shoe" that can be resolved quickly and with minimal resources. This builds momentum and demonstrates the value of the approach without requiring significant upfront investment.

- Use Visual Management: Employ tools like Kanban boards or process charts to make workflows, problems, and improvements visible to everyone. This transparency helps teams see the impact of their changes and identify new opportunities for refinement.

- Standardize and Celebrate: When a successful improvement is made, standardize the new process to ensure consistency. Acknowledge and celebrate these small wins to reinforce the positive behavior and maintain motivation for continuous improvement.

4. Business Process Reengineering (BPR)

Business Process Reengineering (BPR) is a radical and fundamental redesign methodology that challenges organizations to completely rethink their core processes from the ground up. Unlike incremental improvement methods, BPR aims for dramatic, game-changing gains in performance, quality, and efficiency. Popularized by pioneers like Michael Hammer and James Champy, it is one of the more intensive business process improvement methods because it often involves starting with a blank slate rather than making small adjustments.

The central idea of BPR is not to improve what already exists but to invent entirely new and superior ways of working. This approach often leverages technology to enable new process models that were previously impossible. For example, Ford famously reengineered its accounts payable process, reducing its headcount by 75% not by speeding up the old system, but by redesigning the procurement-to-payment workflow around a shared database that eliminated the need for most invoices.

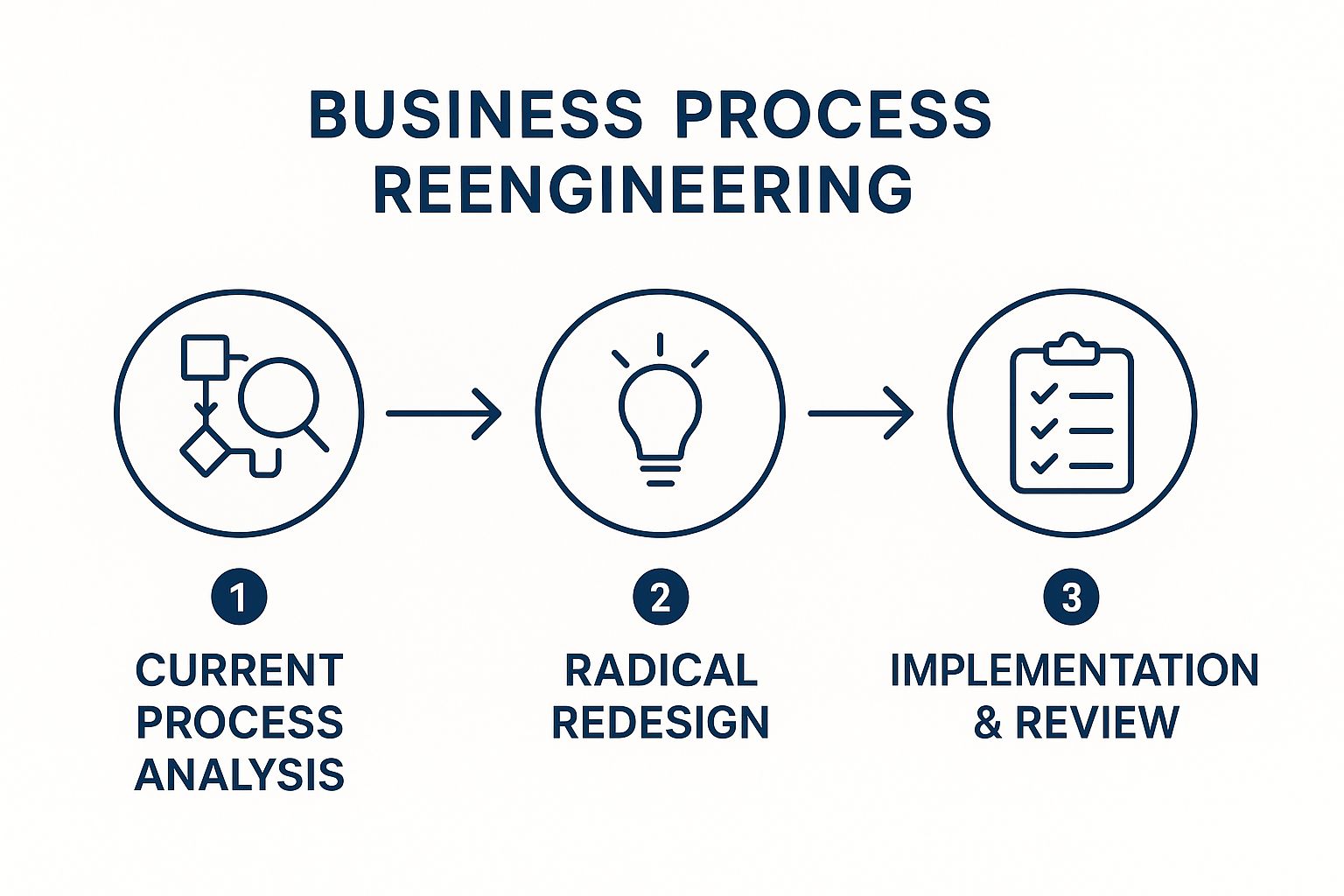

The infographic below outlines the foundational stages of a BPR initiative, showing the progression from understanding the current state to implementing a completely new one.

This visual flow underscores that BPR is a structured transformation, moving deliberately from analysis to a complete overhaul before implementation and review.

When to Use BPR

BPR is best suited for situations where incremental improvements are no longer sufficient to meet strategic goals. It is the right choice when a business faces significant external pressures, such as new, disruptive competitors, or when existing processes are so broken or inefficient that they actively hinder growth and customer satisfaction. A healthcare system might use BPR to completely redesign its patient intake and care delivery model to drastically reduce costs and improve outcomes.

How to Implement BPR

Successful BPR requires strong leadership, a clear vision, and careful planning. Here are the key steps for implementation:

- Secure Executive Sponsorship: BPR is a top-down initiative that requires unwavering support from senior management to overcome resistance and secure necessary resources.

- Identify and Analyze Core Processes: Focus on high-impact, cross-functional processes that are critical to delivering customer value. Thoroughly document the existing "as-is" process to understand its fundamental flaws.

- Redesign from Scratch: Brainstorm entirely new process designs without being constrained by current roles, rules, or departmental structures. Ask "If we were starting this company today, how would we do this?" For a deeper dive into this and other approaches, you can explore some essential process improvement techniques.

- Manage the Change: Communicate the vision and benefits of the change clearly and consistently. Plan for the human side of the transition, including retraining, reorganizing teams, and addressing employee concerns.

5. Agile Methodology

Agile is an iterative methodology that approaches process improvement and project management with a focus on flexibility, collaboration, and rapid delivery. Though it originated in software development, its principles are now widely adopted across diverse industries as one of the most dynamic business process improvement methods. Agile breaks down large projects into small, manageable cycles called "sprints," allowing teams to adapt to change, gather continuous feedback, and deliver value incrementally.

This approach prioritizes customer satisfaction and functional results over rigid, upfront planning. By working in short, focused bursts, teams can quickly respond to new requirements, identify roadblocks early, and ensure the final output is closely aligned with stakeholder needs. It fosters a culture of transparency, communication, and sustained improvement.

When to Use Agile

Agile is most effective in dynamic environments where project requirements are expected to evolve or are not fully known at the outset. It is ideal for complex projects that benefit from frequent feedback and course correction. For example, a legal team developing a new compliance protocol can use Agile to iterate on drafts based on changing regulations, while a hospital can apply it to refine patient care pathways by testing and adapting procedures in real-time.

How to Implement Agile

Adopting Agile involves a shift in mindset from traditional, linear workflows to a more collaborative and cyclical approach. Here are actionable steps to get started:

- Start with a Pilot Project: Select a single, well-defined project to serve as your pilot. This allows your team to learn the Agile process in a controlled environment without disrupting the entire organization.

- Invest in Team Training: Ensure your team understands the core principles and practices of Agile, such as Scrum or Kanban. Training is crucial for fostering the right mindset for collaboration and iterative work. To better understand the stages of Agile adoption and development, explore the Agile Fluency Model.

- Embrace Iterative Planning: Break the project down into short sprints (typically 1-4 weeks). At the beginning of each sprint, the team selects a small batch of tasks to complete from a prioritized backlog. For more ideas on improving your team's processes, you can find great tips for boosting workflow efficiency.

- Use Visual Management Tools: Employ tools like Kanban boards or Scrum boards to visualize workflow, track progress, and identify bottlenecks. This creates transparency and keeps everyone aligned on priorities and status.

6. Theory of Constraints (TOC)

Theory of Constraints (TOC) is a management philosophy that views any complex system, such as a business process, as being limited in achieving more of its goals by a very small number of constraints. Popularized by Eliyahu M. Goldratt, this approach asserts that every process has a single bottleneck, and focusing improvement efforts on that constraint is the fastest path to significant gains. It is one of the most strategic business process improvement methods because it directs resources to the one area that has the greatest impact on overall system performance.

The core idea is that an organization is a chain of linked processes, and the strength of the chain is determined by its weakest link. By identifying and managing this single limiting factor, the entire system's throughput can be elevated. TOC provides a systematic process, the Five Focusing Steps, to break the constraint and then move on to the next one, fostering a cycle of continuous improvement.

When to Use TOC

TOC is exceptionally effective when a process is failing to meet demand or when throughput is a primary concern. It is ideal for identifying and resolving bottlenecks that cause project delays, production shortfalls, or service backlogs. For example, a law firm struggling with slow case turnaround times might discover its constraint is a single senior partner required to approve all filings. A software development team could use TOC to identify that the quality assurance (QA) phase is the bottleneck holding back new feature releases.

How to Implement TOC

Implementing the Theory of Constraints involves a focused, systematic approach. Here are the steps to apply it effectively:

- Identify the Constraint: The first and most critical step is to analyze your workflow to find the one part of the process that limits the pace of the entire system. This is your bottleneck, where work piles up and delays originate.

- Exploit the Constraint: Get the absolute most out of the constrained resource without making major changes. This means ensuring the bottleneck is always working on the right tasks, with no downtime or inefficiencies.

- Subordinate Everything Else: Align all other activities and processes to support the needs of the constraint. Other parts of the system should not work faster than the bottleneck, as this only creates excess work-in-progress inventory and waste.

- Elevate the Constraint: If the previous steps are not enough to meet goals, invest resources to improve the constraint’s capacity. This could mean adding more staff, upgrading technology, or providing specialized training. For more ideas on enhancing system performance, you can explore ways to improve workplace efficiency.

- Repeat the Process: Once a constraint is resolved, a new one will emerge elsewhere in the system. The final step is to return to the beginning and repeat the cycle, ensuring a continuous flow of improvement.

7. Value Stream Mapping (VSM)

Value Stream Mapping (VSM) is a powerful Lean technique used to visualize, analyze, and improve the flow of materials and information required to bring a product or service to a customer. It provides a holistic view of the entire process, not just individual pieces, making it one of the most effective business process improvement methods for identifying systemic waste and process inefficiencies. By creating a visual "map," teams can clearly see where value is created and where delays, bottlenecks, and non-value-added activities occur.

The core of VSM involves charting the "current state" of a process and then designing a more efficient "future state." This visual approach fosters a shared understanding among team members and highlights opportunities for significant improvements that might otherwise go unnoticed. It’s particularly effective for uncovering waste related to waiting, excess inventory, and unnecessary process steps.

When to Use VSM

Value Stream Mapping is ideal when you need a comprehensive, high-level overview of an entire process from beginning to end. It is particularly useful for complex workflows where multiple departments or teams are involved. For example, a hospital can use VSM to map the entire patient journey from admission to discharge, identifying delays in lab results or staff handoffs. Similarly, a software development company can map its pipeline from concept to deployment to reduce lead times and improve release frequency.

How to Implement VSM

Successful implementation of VSM hinges on collaboration and a commitment to seeing the process as it truly is, not as it’s supposed to be.

- Select a Product Family: Start by focusing on a single product or service family to keep the scope manageable. Trying to map everything at once can be overwhelming and counterproductive.

- Walk the Actual Process: Physically walk the path of the value stream yourself. Observe each step, talk to the people involved, and gather real-time data on cycle times, wait times, and resources used.

- Map the Current State: Involve a cross-functional team of participants from every stage of the process to collaboratively draw the current state map. This detailed visualization is crucial and often forms the basis of strong process documentation.

- Design the Future State: Once waste has been identified in the current state map, work with the team to design an improved future state map that eliminates or reduces those non-value-added activities. Create an actionable plan to achieve this new state.

8. 5S Methodology

The 5S Methodology is a foundational workplace organization system that uses five Japanese principles to establish and maintain a clean, orderly, and efficient environment. Developed as a core component of the Toyota Production System, 5S is one of the most fundamental business process improvement methods because it creates the discipline and stability required for more advanced improvements like Lean or Kaizen to succeed. It's built on the idea that a well-organized workspace reduces waste, enhances safety, and boosts productivity.

The five pillars of this methodology, translated from Japanese, are Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). By systematically applying these steps, an organization can eliminate clutter, ensure tools and materials are always in their designated place, and embed a culture of continuous cleanliness and order. This is the bedrock of operational excellence.

When to Use 5S Methodology

The 5S methodology is universally applicable but is especially powerful in environments where physical tools, inventory, or documents are critical to the workflow. It's a perfect starting point for any organization beginning its process improvement journey. For instance, a hospital can use 5S to organize operating rooms and supply closets, ensuring critical equipment is always accessible and sterile. Similarly, a law firm can apply 5S principles to its file management system, both physical and digital, to drastically reduce the time spent searching for case documents.

How to Implement 5S Methodology

Successful implementation of 5S relies on total team participation and making it a daily habit rather than a one-time project. Here are actionable steps to get started:

- Start with a Red Tag Event (Sort): Go through a specific work area and place a red tag on every item that is not essential for the immediate tasks. Move these items to a holding area and decide whether to discard, relocate, or store them.

- Create Visual Workplaces (Set in Order & Shine): Once only necessary items remain, designate a specific home for everything using visual cues like shadow boards, floor markings, and labels. Follow this with a thorough cleaning of the area, making it a standard to keep it that way.

- Establish Standards and Sustain (Standardize & Sustain): Document the new layouts and cleaning schedules. Create checklists and assign responsibilities to make 5S part of the daily routine. Conduct regular audits to ensure compliance and prevent the workspace from reverting to its previous state.

9. Design Thinking

Design Thinking is a human-centered, iterative approach to problem-solving and innovation that focuses on understanding the end user's needs to drive process improvements. It integrates the needs of people, the possibilities of technology, and the requirements for business success. As one of the more creative business process improvement methods, it encourages organizations to challenge assumptions and redefine problems in order to identify alternative strategies and solutions that might not be instantly apparent with an initial level of understanding.

The core of Design Thinking revolves around a five-phase process: Empathize, Define, Ideate, Prototype, and Test. This structured framework, popularized by Stanford's d.school and IDEO, guides teams from deep user understanding to tangible, validated solutions. This method is exceptionally powerful for tackling complex or ill-defined problems where the human element is paramount.

When to Use Design Thinking

Design Thinking is most effective when improving processes that directly impact user or customer experience. It is ideal for situations where the problem is not well understood or when innovative, rather than just incremental, solutions are needed. For example, a hospital can use Design Thinking to completely redesign the patient admission process to reduce anxiety and improve efficiency. A legal tech company could apply it to develop a new contract management platform that is intuitive for lawyers with no technical background, directly addressing user pain points.

How to Implement Design Thinking

Implementing Design Thinking involves a shift towards empathy and experimentation. Here are actionable steps to get started:

- Start with Empathy: Conduct in-depth user research. Use methods like interviews, observations, and surveys to gain a deep understanding of your users' experiences, motivations, and pain points. This is the foundation of the entire process.

- Embrace Ideation: In the ideation phase, encourage wild and diverse ideas without judgment. The goal is to generate a large volume of potential solutions. Techniques like brainstorming and "worst possible idea" can unlock creative thinking.

- Prototype and Test Rapidly: Build low-fidelity prototypes of your potential solutions. These can be as simple as a storyboard or a clickable wireframe. Test these prototypes with real users early and often to gather feedback.

- Iterate Based on Feedback: Use the insights from testing to refine your solution. Design Thinking is not linear; expect to cycle back through the phases as you learn more. This iterative loop is crucial for developing a truly user-centric and effective process.

9 Key Business Process Improvement Methods Compared

| Methodology | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Lean | Moderate; requires cultural change and training | Moderate; cross-functional teams, training | Waste reduction, faster delivery, cost savings | Manufacturing, operations with waste focus | Efficient operations, employee empowerment |

| Six Sigma | High; complex statistical tools and training | High; data analysts, training, software | Near-perfect quality, reduced defects | Quality-critical processes | Data-driven, measurable quality improvements |

| Kaizen | Low to moderate; cultural shift needed | Low; employee involvement | Continuous small improvements, sustainable change | Organizations fostering ongoing improvement | Builds improvement culture, quick wins |

| Business Process Reengineering (BPR) | Very high; radical redesign and disruption | Very high; technology, management support | Dramatic performance improvements, competitive edge | Processes needing fundamental overhaul | Radical improvements, eliminates outdated processes |

| Agile Methodology | Moderate; requires experienced teams | Moderate; collaborative teams | Faster time to market, flexibility | Software development, dynamic projects | Rapid delivery, continuous feedback |

| Theory of Constraints (TOC) | Moderate; system understanding needed | Moderate; analysis and coordination | Increased throughput, clear priorities | Processes with identifiable bottlenecks | Focused improvement efforts, improved flow |

| Value Stream Mapping (VSM) | Moderate; detailed process visualization required | Low to moderate; training and involvement | Process clarity, waste identification | Process improvement, lean initiatives | Clear visibility, data-driven decisions |

| 5S Methodology | Low; requires discipline and ongoing maintenance | Low; employee participation | Organized, safe, efficient workplaces | Workplace organization | Builds discipline, reduces waste |

| Design Thinking | Moderate to high; iterative and time-intensive | Moderate; cross-functional collaboration | Innovative, user-centered solutions | Innovation, product/service design | Encourages creativity, reduces solution risk |

Choosing Your Path to Process Excellence

The journey toward operational excellence is not about finding a single, magic-bullet solution. As we have explored throughout this guide, the landscape of business process improvement methods is rich with diverse, powerful, and adaptable frameworks. From the waste-elimination focus of Lean and the defect-reduction precision of Six Sigma to the continuous, incremental enhancements championed by Kaizen, each methodology offers a unique lens through which to view and refine your organization's operations.

The true challenge, and opportunity, lies not in picking one method and discarding the others, but in understanding which tool is right for which job. A radical transformation might call for Business Process Reengineering (BPR), while refining a specific, document-heavy workflow might benefit from the focused visual clarity of Value Stream Mapping (VSM) or the organizational discipline of the 5S Methodology. For professionals in highly regulated fields like healthcare and law, this choice is particularly critical. Inefficiency isn’t just a drain on resources; it can impact patient care, case outcomes, and regulatory compliance.

Synthesizing Methodologies for Maximum Impact

The most mature and successful organizations rarely adhere dogmatically to a single framework. Instead, they create a hybrid approach, a customized toolkit that draws from the strengths of multiple business process improvement methods. This strategic blending allows for a more nuanced and effective response to complex challenges.

Consider these potential combinations:

- Lean and Six Sigma (Lean Six Sigma): This is the most common hybrid, combining Lean's speed and efficiency focus with Six Sigma's quality and statistical rigor. It's a powerful duo for tackling processes where both waste and errors are significant problems, such as in medical billing or patient intake procedures.

- Agile and Kaizen: Infuse your Agile sprints with a Kaizen mindset. Use the end-of-sprint retrospectives not just to review the work but to identify small, continuous improvements to the development process itself. This creates a powerful feedback loop for constant refinement.

- BPR and Design Thinking: When undertaking a massive overhaul with BPR, use Design Thinking principles to ensure the new process is built around the end-user’s actual needs, whether that user is a client, a patient, or an internal team member. This human-centered approach prevents the creation of a theoretically efficient but practically unusable system.

The key takeaway is that these frameworks are not mutually exclusive. They are complementary tools in a comprehensive arsenal. Your role as a leader is to diagnose the problem accurately and then select the right combination of tools to forge a solution.

Your Action Plan: From Theory to Tangible Results

Moving from understanding these concepts to implementing them is the most critical step. Abstract knowledge provides no value until it is applied. For legal professionals, healthcare providers, and compliance officers, the path forward involves a commitment to action, supported by the right technology.

Here is a practical, step-by-step plan to begin your journey:

- Identify a Single, High-Impact Process: Don't try to boil the ocean. Select one process that is a known source of frustration, delay, or cost. This could be client onboarding, medical record documentation, or compliance reporting.

- Diagnose the Core Problem: Is the issue waste (Lean), variation and errors (Six Sigma), a system bottleneck (TOC), or a poor user experience (Design Thinking)? Your diagnosis will point you toward the most appropriate methodology.

- Empower a Cross-Functional Team: Assemble a small team of individuals who directly touch the process. Their firsthand knowledge is invaluable. Grant them the authority to experiment and make changes.

- Integrate Enabling Technology: Modern process improvement is inseparable from technology. In document-intensive fields, inefficiencies in paperwork are a primary target. A tool that directly reduces the time spent on documentation is a powerful lever for change. By automating transcription and simplifying document creation, you directly attack a common bottleneck, freeing up highly skilled professionals to focus on their core competencies.

- Measure, Iterate, and Scale: Define your success metrics before you start. Measure the baseline, implement your changes, and then measure the impact. Use the results to refine your approach and, once successful, identify the next process to improve.

Embarking on a business process improvement initiative is a definitive statement about your organization's commitment to excellence, resilience, and future growth. It is an investment in your people, your clients, and your bottom line. The path may be challenging, but the rewards—a more efficient, agile, and competitive organization—are well worth the effort.

Ready to eliminate a major bottleneck in your documentation workflow? Whisperit uses advanced AI to provide fast, accurate, and secure dictation and transcription, allowing legal and medical professionals to complete paperwork up to two times faster. Integrate powerful technology into your business process improvement methods and reclaim your most valuable asset: time. Explore Whisperit today and take the first step toward a more efficient practice.